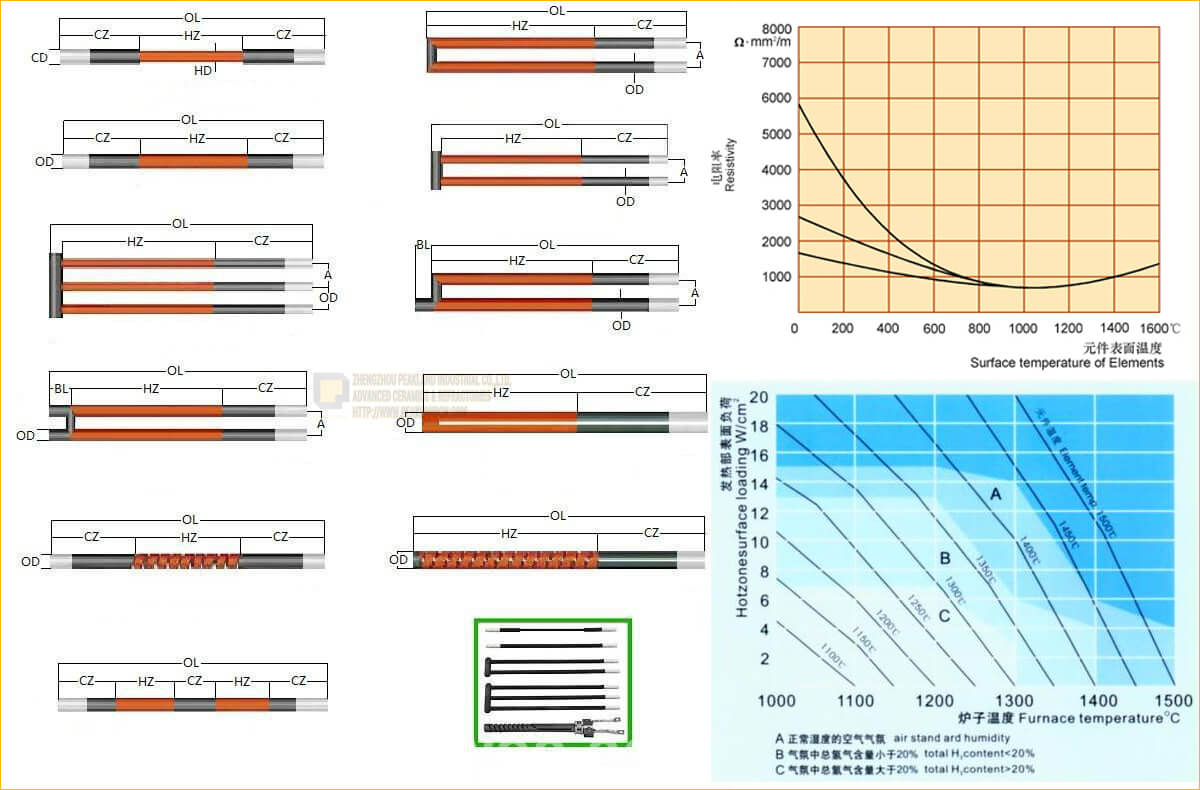

SiC Heating Elements

PEAKLAND Silicon Carbide Elements are made of selected super purity green hexagonal silicon carbide as main material, which is made into blank and silicon crystal under high temperature of 2400ºC.

PEAKLAND Silicon Carbide Elements are made of selected super purity green hexagonal silicon carbide as main material, which is made into blank and silicon crystal under high temperature of 2400ºC.

ZHENGZHOU PEAKLAND INDUSTRIAL CO., LTD.

Address

No. 5, Taohuali, New & High-Tech. Development Zone, 450000, Zhengzhou, Henan Provience, P.R.China.

Contact

Attn: Chris Chyi (Sales Engineer.)

Mobile/WeChat/Whatsapp:

+86-18637192800

Tel/Fax: +86-371-61310120

Email: sales@peaklandcn.com